Focus on Surface Finishing For 30 Years

One-stop Surface Finishing Solution Provider

+86-572-3626718

Qianwushan Industrial Area, Shuanglin Town, Nanxun District, Huzhou City, Zhejiang Province

One-stop Surface Finishing Solution Provider

+86-572-3626718

Qianwushan Industrial Area, Shuanglin Town, Nanxun District, Huzhou City, Zhejiang Province

+86-572-3626718

Qianwushan Industrial Area, Shuanglin Town, Nanxun District, Huzhou City, Zhejiang Province

Features

1. The equipment is mainly composed of grinding barrel, base, electrical cabinet and other parts. It is suitable for grinding operations such as medium and small-sized workpieces and high-precision workpieces. It has strong cutting force and uniform grinding force.

2. The equipment consists of a rotating disc at the bottom and a polygonal fixed grinding tank to form a working grinding barrel. The rotating disc is made of aluminum alloy, which is light in weight and wear-resistant. The inner wall of the grinding tank is made of wear-resistant polyurethane PU glue.

3. The equipment uses the centrifugal force generated by the high-speed rotation of the bottom rotating disc to cause strong friction between the workpiece and the abrasive in the grinding barrel, forming a spiral vortex motion, so that the workpiece and the abrasive produce high-speed rotary friction and spiral flip, and finally the processed parts can be It is evenly deburred or polished in a short time to achieve the ideal processing effect.

4. The base is welded by steel plates, and the middle of the base is a water receiving tray. During the operation of the machine, the sewage in the grinding barrel can be directly discharged into the water receiving tray, and then the sewage is discharged through the drain at the bottom of the water receiving tray.

configuration options

1. Independent control electric cabinet: it is convenient for the safe operation of the equipment, prevents the overload of the motor current, sets the running time, starts and stops the equipment and other functions.

2. Frequency converter: the frequency range is adjustable, and the effect of adjusting the speed of the grinding barrel can be achieved by adjusting the running speed of the equipment motor.

3. The basic configuration model is manual discharge, and the automatic flip discharge and automatic feeding functions can also be configured according to customer needs.

4. It can be matched with the vibrating screen to automatically sort workpieces and abrasives.

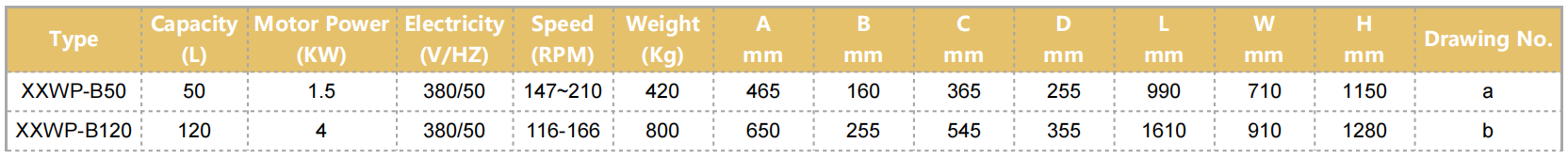

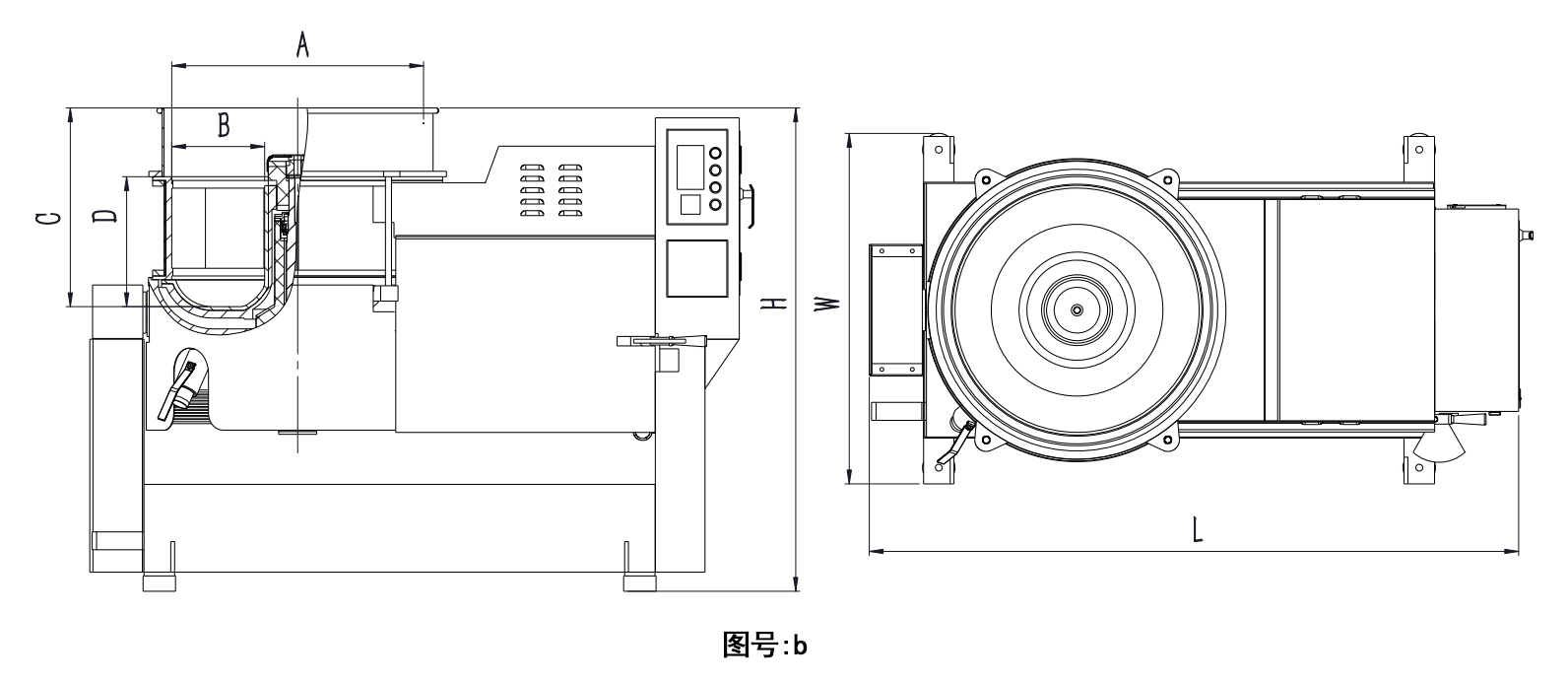

parameter

drawing

Huzhou Xingxing Abrasive Co., Ltd. is a company specializing in surface finishing field. Our company has been engaged in this field since 1 9 9 7. We are a reputable nation-wide supplier of mass finishing media, mass finishing machinery and ceramic grinding balls....Learn More