Focus on Surface Finishing For 30 Years

One-stop Surface Finishing Solution Provider

+86-572-3626718

Qianwushan Industrial Area, Shuanglin Town, Nanxun District, Huzhou City, Zhejiang Province

One-stop Surface Finishing Solution Provider

+86-572-3626718

Qianwushan Industrial Area, Shuanglin Town, Nanxun District, Huzhou City, Zhejiang Province

+86-572-3626718

Qianwushan Industrial Area, Shuanglin Town, Nanxun District, Huzhou City, Zhejiang Province

Features

1. This series of eddy current grinding and polishing machines is a new type of high-precision finishing machine integrating wet grinding and dry grinding and polishing. It can perform stepwise multi-level surface grinding and polishing continuous operations according to customer needs.

2. Adopting the principle of vortex flow, the processing efficiency is high and the workmanship is exquisite. It is especially suitable for the batch processing of small parts such as jewelry, clocks, glasses, and electronic hardware. It adopts a unique compact gap adjustment structure design, which is suitable for the surface finish of ultra-thin workpieces. decorative treatment.Compared with traditional manual grinding, polishing has the advantages of high processing efficiency, labor saving, exquisite workmanship, good consistency, and uniform surface gloss.

3. The model has the characteristics of compact and reasonable structure, convenient operation, large speed range (forward and reverse rotation can be switched at regular intervals), balanced operation, low noise, and high grinding efficiency.

4. The machine structure is mainly composed of grinding barrel, frame, sorting device (configured for 20L model), circulating water system (wet type), and electrical control box.

5. This series of models is divided into two main types with a capacity of 20L and 38L according to the volume of the grinding barrel.

6. The grinding barrel body is made of high wear-resistant polyurethane PU glue poured at one time. The material and ultra-thick design determine the long service life of the grinding barrel.

7. The speed of the rotary table is adjusted by the frequency converter, which is energy-saving and practical: the rotary speed of the 20-liter capacity model is 0-450 rpm, and the 38-liter capacity model is 0-400 rpm.

8. The equipment adopts manual turning and discharging, and is assisted by gas springs, which is labor-saving and easy to operate.

9. The equipment is designed with an automatic circulating water treatment system, which is easy to operate, low in noise and high in grinding efficiency.

configuration options

1. Independent control electric cabinet: it is convenient for the safe operation of the equipment and protects the motor from overloading. An automatic PLC electric control cabinet (with touch screen) is also available.

2. Working voltage: 220V or 380V can be selected for the 20L capacity model, and 380V for the 38L capacity model.

3. Frequency converter: the frequency range is adjustable, and the effect of adjusting the speed of the grinding barrel can be achieved by adjusting the running speed of the equipment motor.

4. The 20L capacity model is equipped with a sorting device.

5. Optional wet polishing or dry polishing machine configuration.

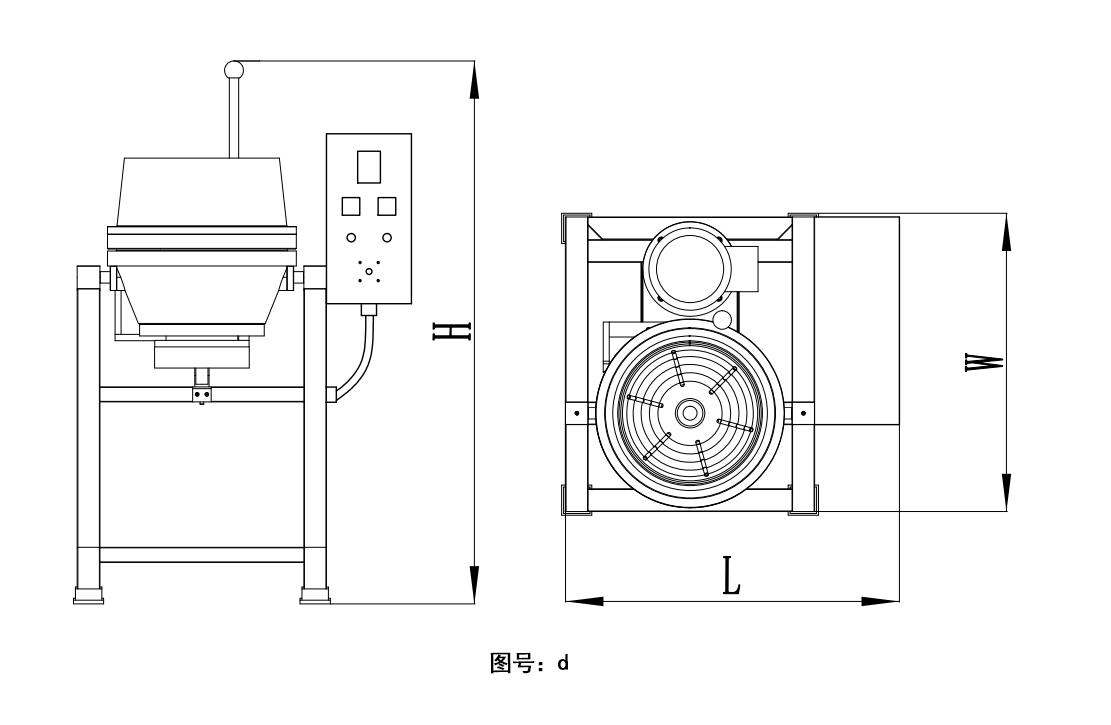

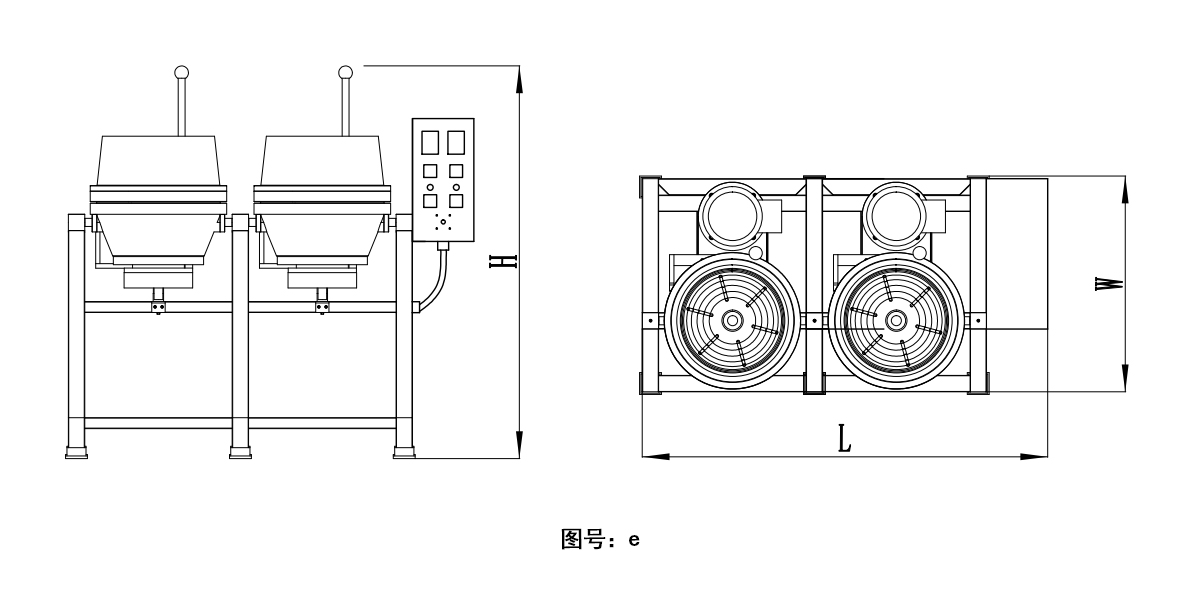

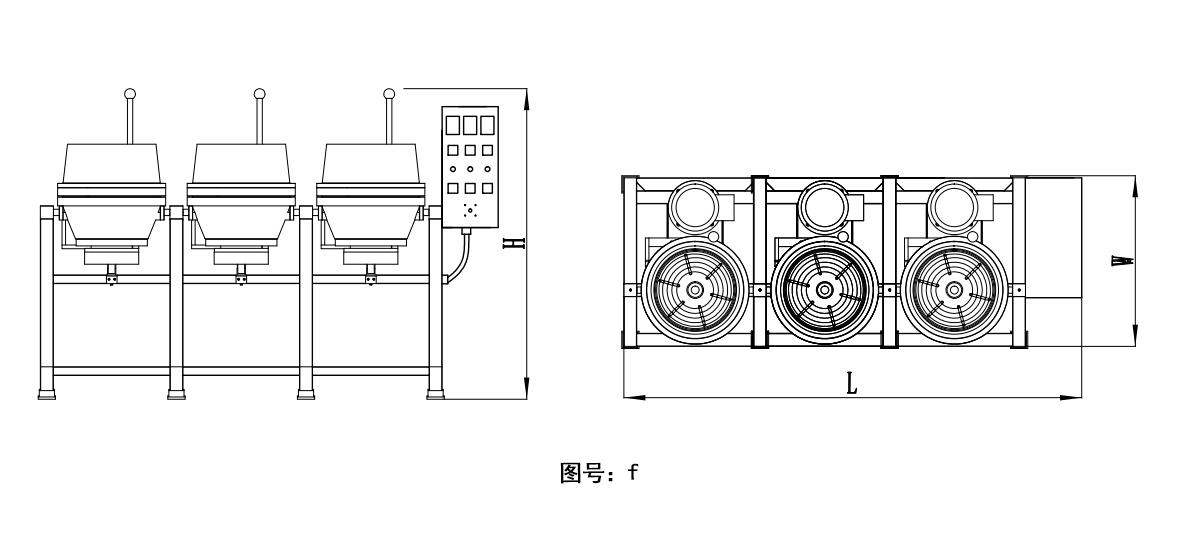

6. The equipment has three types: single barrel, double barrel and three barrels, and customers can choose according to their needs.

7. The wet grinding barrel is equipped with a circulating water device and a sedimentation tank, and the circulating water device has an adjustable switch to control the water supply required for grinding.

drawing

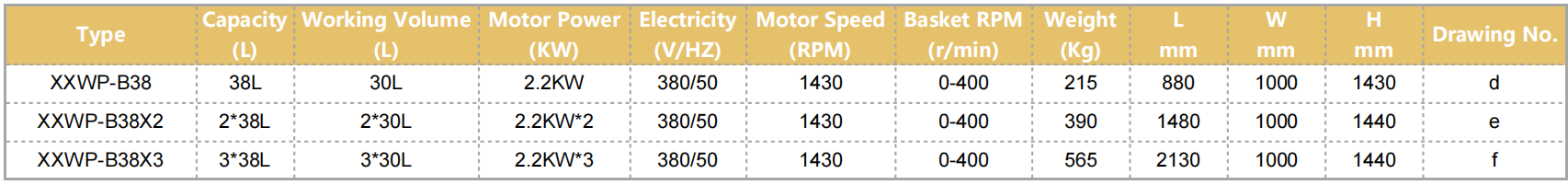

parameter

Huzhou Xingxing Abrasive Co., Ltd. is a company specializing in surface finishing field. Our company has been engaged in this field since 1 9 9 7. We are a reputable nation-wide supplier of mass finishing media, mass finishing machinery and ceramic grinding balls....Learn More